Building a High-Performance Engine

This article demonstrates the complete process to build a high-performance or race engine. This has been developed and refined by PBMS for use with our engine program.

.png)

7 Steps to Reliable Performance

We’ve developed a 7 step process to ensure consistency in the reliability and performance of the engines we build. Whether it’s a stock rebuild or a big power motorsport engine, we aim to provide our customers with quality!

We’ve detailed the build process further down the page, but first, we’ll start with build planning and component selection.

.png)

Build planning

A clear plan of your intended use of an engine, and how you’re going to achieve that is a critical starting point. You’ve probably heard the saying, “if you fail to plan, you plan to fail”. This is particularly important when planning an engine build, as failure is often very expensive. Here’s the thought process to follow when planning a build:

1. Decide on your intentions. What is the intended use of your engine? Is it simply a stock road car that needs a rebuild? Maybe a performance road car that you still want to daily drive? Do you want to produce some serious power for a weekend warrior and track day machine? Or, is this going to be a dedicated race engine?

2. Drivability. How would you like the car to drive, and does that match your intention? Consider powerband, economy, low RPM cruise, and maximum high RPM power.

3. Consider the whole package. How will it fit with the rest of the build? Do the components all support the same power level? Is the specification of the camshafts, manifolds, and turbo suitable for the same power band? Will everything in the whole package achieve your initial intention?

4. Future-proofing. What’s the chance you’re going to want more power out of the engine in the future? This should be carefully considered from the beginning, as upgrading internal components often require an additional engine build at a significant cost.

5. Building in Stages. In some instances, you may want to build an engine to handle significant power and perform external upgrades in stages. This will give you a solid base, but also allow you to increase power as you become used to driving it, or as budget allows.

6. Longevity. The final consideration you need to consider is the longevity of your performance or race engine. As the demands on an engine increase, the requirement for maintenance, repair, and future rebuilds increase. This is particularly important to keep in mind when building an ultra-powerful engine, or a front-running race engine.

If you’d like to have PBMS build your next engine and run you through the complete Build Planning process contact us.

.png)

Component selection

Over the years, we’ve learned what it takes to build a strong engine that will last the test of time. Selecting the right parts for the job is undoubtedly one of the most critical elements when it comes to success.

Here’s our philosophy when it comes to selecting the components we use in a build.

1. Reputation is everything. We only work with quality brands that we know and trust, because a failure for a customer is a failure for us.

2. Tried and tested. We look to use components that have been tried and tested for the power level and application they’re destined for. If we’re developing a new package, we use our engine-building expertise and consult the experts (see below).

3. Consult the experts. If we’re building an engine package that’s unique or new to us, we go straight to the experts. This means we’ll deal directly with the manufacturers to select the perfect cam-shaft to suit your turbo and make sure that the con-rods will be able to handle the torque we expect your combo to make.

Engine Build Process Overview

Each Complete Engine or Short Block follows our 7-Step Engine building process:

1. Disassembly and cleaning - The engine or short block is completely torn down and components under consideration for re-build are cleaned.

2. Inspection and checking - All components to be used in the build are inspected, measured, and tested to ensure suitability and quality.

3. Component preparation - Specific components are prepared once they have passed inspection. This includes modification and light machining work.

4. Machining - All required machine work is completed to our specific tolerances.

5. Blueprinting - Core components are measured and sizing or limits checked and adjusted to ensure they will give maximum engine life and performance. after preparation and machining to ensure they match our ‘Blueprint’ specs.

6. Final assembly - All components are given a final clean and assembled by our professional engine builders.

7. Documentation and tagging - All measurements and components used are recorded for future reference and an engine tag is applied to the block for identification.

Step 1: Engine Disassembly and cleaning

Either a complete car is dropped off at PBMS for our Specialised Technicians to remove the engine or customers may prefer to have the engine removed closer to home and shipped to PBMS in Pukekohe, New Zealand - or - use a locally sourced donor engine.

When an engine is ready to start the process, it is completely disassembled by one of our Engine Builders. All components are thoroughly cleaned either by hand or in a Turbowash to prepare them for the following steps.

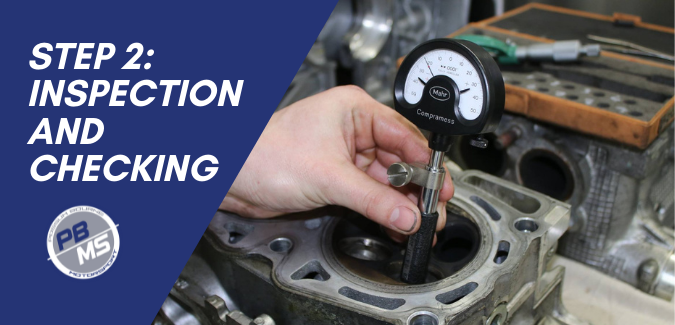

Step 2: Inspection and checking

We’ve got a pretty high standard at PBMS, so we go the extra mile when it comes to inspecting and measuring all engine components that go into a build.

If we’re re-using an existing component from the engine, we inspect it with a fine-tooth comb to ensure it’s going to be suitable for the performance level in mind. Even if the component is brand-new, we don’t leave anything to chance. We perform the same checks to maintain a high-quality build.

The specific checks vary between components, but normally include many of the following:

- Crack testing

- Hardness testing

- Check for straightness

- Ultrasonic thickness testing

- Pressure testing

- Bearing journal sizing

- General damage and wear assessment

- Component weighing

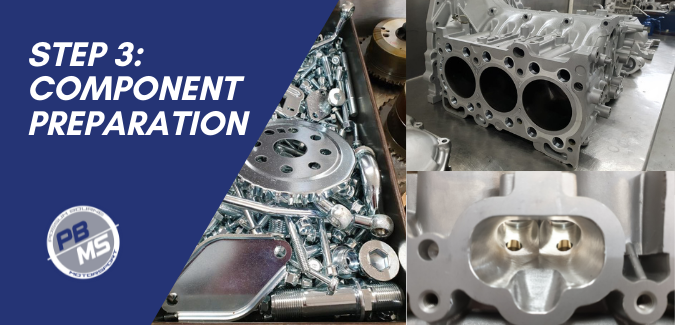

Step 3: Component preparation

This is where we modify and prepare engine components to use in a high-power or performance engine. This ranges from simple cosmetic tasks for aesthetic purposes, to modification, clearancing, and engine upgrade work.

The exact work we do here will be dictated by the level of the engine, but may include:

- Vapour blasting

- Engine balancing

- CNC Block Machining (Including our own closed deck modification)

- Installing liners/sleeves

- Oil gallery modifications

- Cylinder head porting

- Cylinder head clearancing for large cams

- Balance shaft deletion

- Drilling and tapping for larger head-studs

- Coatings, painting, and plating

Step 4: Engine Machining

Machining work typically involves precision grinding, surfacing, or CNC/milling of the cylinder head and engine block. It’s usually carried out for the following reasons:

1. Renew or repair any damaged and worn components

2. Machine surfaces to be straight and true

3. Bore and/or hone to suit new pistons.

Common machine work to be carried out includes:

Cylinder head:

- Deck resurfacing

- Valve guide replacement

- Valve seat cutting

- Valve grinding

Engine Block:

- Deck resurfacing and squaring

- Line boring and honing (for crankshaft)

- Cylinder boring and honing

Step 5: Blueprinting

Once all components have been prepared and machining is complete, a re-inspection and re-measurement are performed. In a high-performance or race application, there are very specific tolerances that need to be achieved.

Through measurement and even dummy assembly, we check to ensure that all critical measurements match our specifications and will be suitable for their intended high-performance purpose. This results in a Blueprinted engine.

Step 6: Engine Final assembly

With all components and clearances having passed our quality control checks, a final clean is performed to ensure no foreign contaminants are present within the engine.

Our professional engine builders then completely assemble the engine using both OEM recommendations and aftermarket requirements as necessary.

Final measurement and adjustment of piston-to-deck heights, value clearances, and cam timing are made.

Step 7: Documentation and tagging

During the engine building process, our engine builders document the parts and measurements made for quality control and future reference. This includes part and batch numbers, and the specific tolerances the engine has been built to.

To make the block easy to identify in the future, a tag with a unique serial number is added.

If you’d like to have PBMS build your next engine contact us.