You're looking at building a performance or motorsport Subaru engine. You've looked on the internet and seen the common 2.0L engines, the stroked 2.1L, the larger 2.5L engine and the de-stroked 2.35L builds. How do you know what you should build? We’ve built everything from high revving 1.8L EJ engines, right through to mega-displacement 2.7L stroker motors. There are so many options, so we’ll look into what will make an engine that suits you! The place to start, is considering the factors that will guide your decision - then look at comparing the common engines.

Cost

The first thing to consider is budget. Cost will typically increase the more power you want an engine to be able to handle, and the more complex the build. If you're going to keep the displacement standard, this reduces the requirement for obscure parts and reduces the labour cost involved in measuring, calculating and adjusting clearances as required.

Time

Similar to cost, a more complex build will typically take longer and may require parts not immediately available. A simple build will provide for a faster turn around.

Reliability

Any engine requires adequate maintenance, quality tuning and to run within it's designed parameters for it to be reliable. In the context choosing what engine to run, you'll need to select an engine that will do the job for your requirements, and keep it within the designed power level and rev-range.

Power handling

When designing any engine package, it is very important to have a clear idea of the power and torque you're aiming for. This allows us to ensure the individual components will support the power and the entire package will be well matched to work together.

Power band

The different engine combinations will effect the response and what the maximum recommended rev limit is. The block is just one-part of the engine/cylinder head/turbo combination which will ultimately dictate the power band. In general, the smaller the piston and the shorter the stroke, the more an engine is happy to rev. The greater the displacement and the longer the stroke, the more response and low-down torque an engine will be able to produce. Engine balancing can improve the rev-range above a factory limit.

Combinations to consider

After considering the factors, we'll take a look at specific engine options. To keep things simple, we'll focus on the more common variations.

2.0L

The 2L STI engine is the bench-mark of reliability and great all-round performance in factory form. When comparing to other built engines; these are simple, reliable and love to rev. Being the smallest displacement they have least response and torque, particularly noticeable when moving to larger turbo sizes. We use them in everything from simple street car builds to high-revving-big-power motorsport weapons.

2.1L

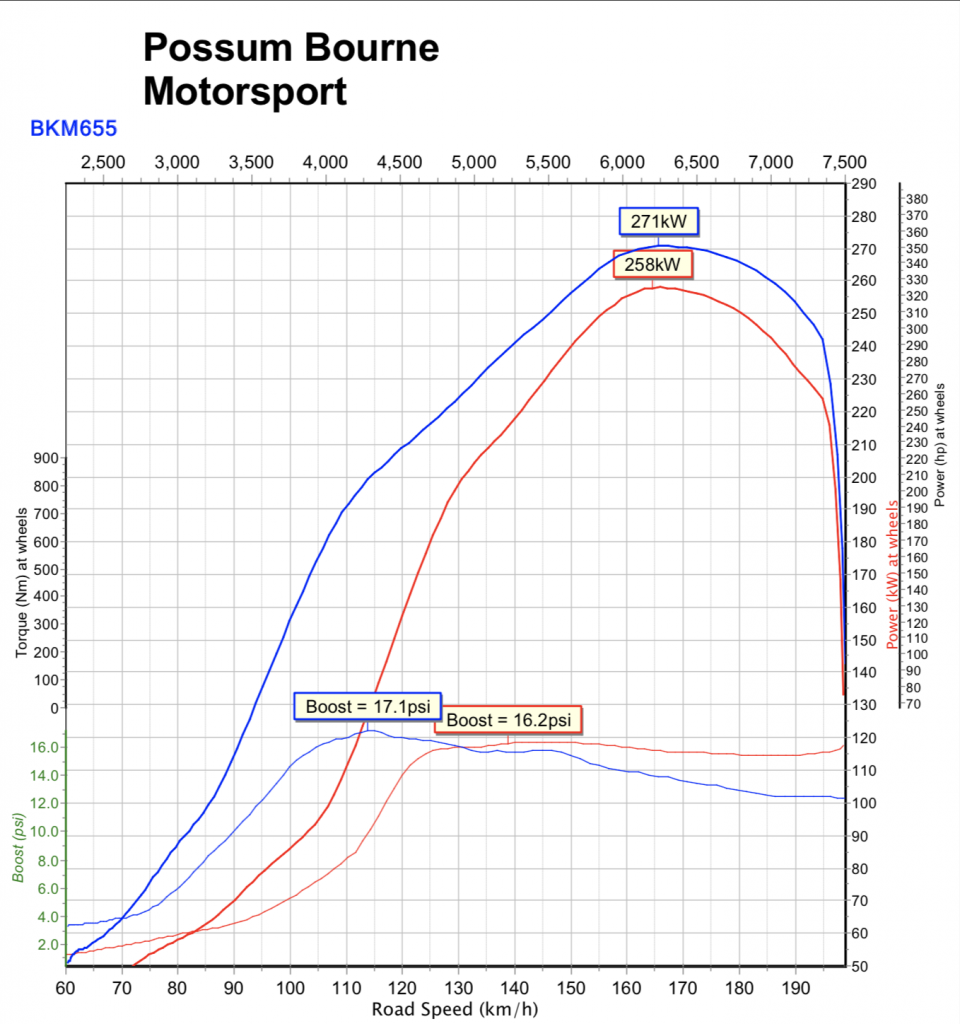

The 2.1L stroker is based on a 2L block with a stroker crank and custom pistons to suit. The addition displacement and longer stroke provides a significant improvement in response and the ability to spool a turbo. The longer stroke does promote better low down and mid-range at the sacrifice of high-end revs. Custom pistons are required and typically need additional piston-valve clearance, adding time and cost. We use these in 2L based vehicles to improve torque, including street cars with larger turbos and motorsport vehicles where response and low-mid range is ideal such as rally and targa classes. [caption id="attachment_1842" align="alignnone" width="960"]

Comparison between 2.0L stock engine (with turbo and supporting upgrades) vs built 2.1L stoker and PBMS stage 3 cylinder heads. Real world results gave 1000RPM+ improvement in response and turbo spool.[/caption]

2.5L

The 2.5L factory engine has long had a few question marks over reliability. With advancements in technology, a thorough engine build and quality tune can provide an incredibly fun engine with great reliability. The biggest advantage of a 2.5L comes from the large piston size and longer stroke, giving it more displacement. As the Yanks say "There's no replacement for displacement". This gives them the best response and torque, with the ability to spool a large turbo well. The sacrifice here is in the ability to pull big revs, however a balanced engine can reduce this disadvantage. Components are available off-the-shelf making this an easy combination. A built 2.5L works exceptionally well in a street car or something with a large turbo. The displacement makes these engines easy to drive. If using a 2.5L bottom end with cylinder heads designed for a 2.0L, PBMS recommend modification to the cylinder head squish area to get the best performance.

2.35L

This is essentially the opposite to a 2.1. Using a 2.5L block with a reduced-stroke crankshaft and custom pistons or custom rods reduces the capacity to 2.35L. This engine will rev high whilst have reasonable displacement for spool and response. This engine is essentially the middle-ground between a 2L and a 2.5L. Being a custom setup with less off-the-shelf parts, time and costs are increased. We use this setup in cars that need to rev but displacement is also an advantage, including big-turbo street and drag cars. Again, using a large 2.5L-sized piston with cylinder heads designed for a 2.0L, PBMS recommend modification to the cylinder head squish area to get the best performance.

Custom

We've used other combinations in the past for specific performance and motorsport goals. These have included a 2.5L stroked to 2.7L, as well as a 2L rally engine stroked to 2.3L. PBMS can design an engine package to suit your needs, so get in touch today.

If you have any further questions or would like to plan a performance/motorsport engine, please contact us today.